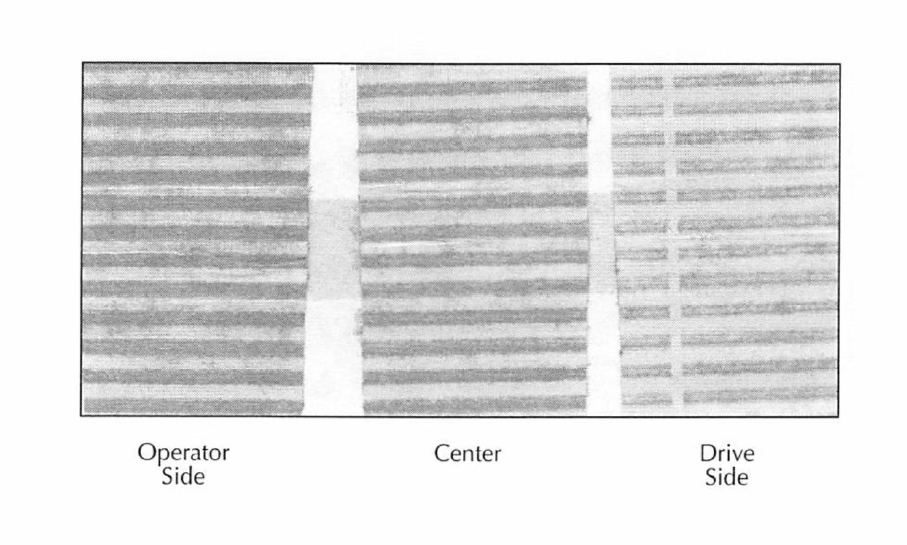

The issue is related to uneven corrugating roll nip pressure loading. This can cause non-uniform wear and variable quality convertibility across the sheet of combined board. The heavy pressure on the operator's side and light pressure on the drive side is a clear indication of this issue. There could be a few causes for this problem. It could be due to hydraulic, pneumatic, or manual pressure adjustment being out of control. In this case, adjusting and equalizing roll pressure can help. Another possible cause could be loading gauge being out of calibration, which can be fixed by checking and correcting the gauges. Lastly, if the pressure cylinders are malfunctioning, repairing the malfunction in pressure cylinders can resolve the issue.

There could be a few causes for this problem. It could be due to hydraulic, pneumatic, or manual pressure adjustment being out of control. In this case, adjusting and equalizing roll pressure can help. Another possible cause could be loading gauge being out of calibration, which can be fixed by checking and correcting the gauges. Lastly, if the pressure cylinders are malfunctioning, repairing the malfunction in pressure cylinders can resolve the issue.