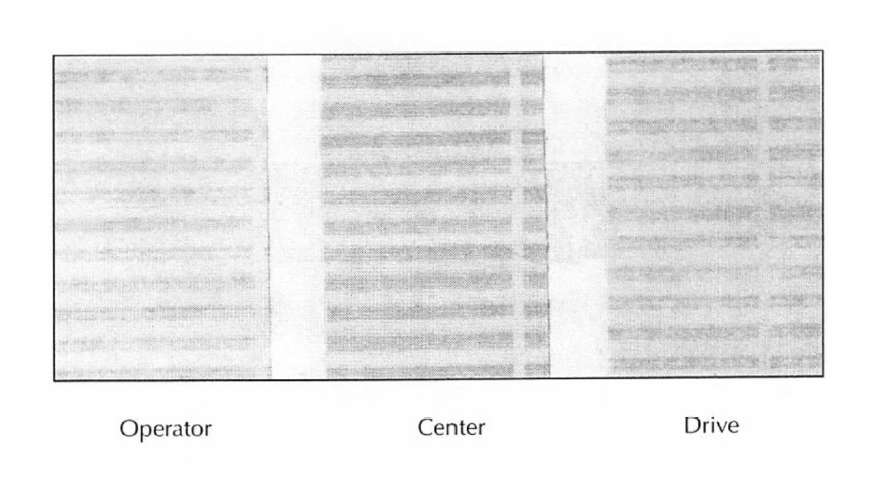

Uneven corrugating roll nip pressure - High in Center

Several factors may contribute to this problem, including hydraulic, pneumatic, or manual pressure adjustments being out of control. In such a case, adjusting and equalizing roll pressure can help alleviate the issue. Another possible factor could be an out-of-calibration loading gauge, which can be resolved by checking and correcting the gauges. Lastly, if the pressure cylinders are malfunctioning, repairing the malfunction in pressure cylinders can resolve the issue.

It is worth noting that this issue can cause excessive wear in the center and variable convertibility across the sheet, leading to a reduction in the quality of the final product. Therefore, it is crucial to address the problem promptly and accurately.

|

Enter your email address to subscribe to this blog and receive notifications of new posts by email. |