Single Facer

Doublebacker

Double baker is a type of wet end machine that is used to convert liner into board with multiple layers, such as 3 ply, 5 ply, or 7 ply. It is a critical component of the paper manufacturing process, particularly for producing high-quality packaging materials. The machine helps to bond the different layers of liner together using heat and pressure, resulting in a strong and durable board that can be used for a variety of packaging applications.

Splicer

Hot Plates

I just wanted to remind you about the hot plates at the dry end process. You can use the hot plate in this section to dry sheet (boards) and control moisture for an effective way to maintain board quality. However, it's important to take proper precautions and follow safety instructions when using the hot plate. Be sure to monitor the board closely to prevent over-drying or damage, and consider using a humidity gauge to ensure that moisture levels are being controlled effectively. Additionally, for the top finishing of the board, it's important to clean the hot plate belt properly. Steam washing should be done at least every 6 months.

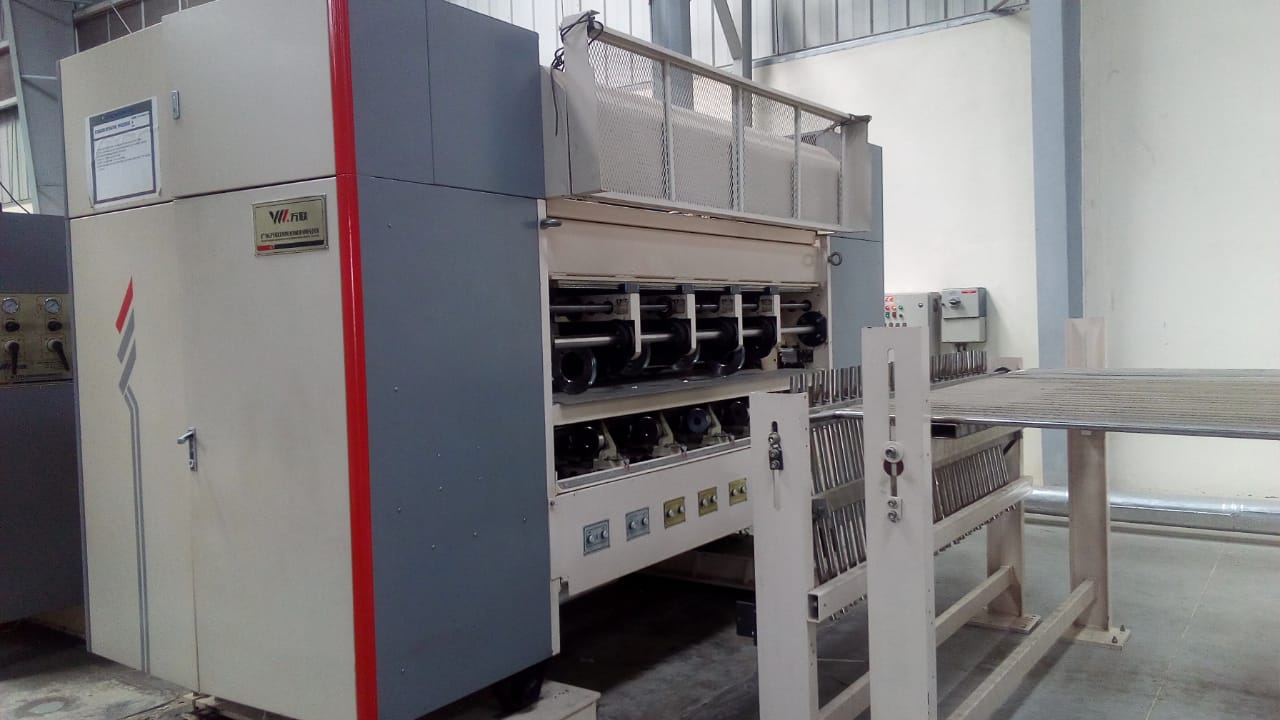

Slitter and Scorer

This machine is quite interesting. It is called a Sleater and Scorer and it is used to cut large uncut corrugated sheets into smaller ones, based on the printing machine's needs. This machine is quite important in cutting board from a deckle vise and it provides scoring for the sheet flap height according to the RSC box. The female creasing creases the top side of the board, while the male creaser creases the bottom.

Popular Posts

Tags

Home Keyline Types of Box Live Class Jobe Corrugation Industrries Defects Formulas Printing Corrugation Defects in box Line defects Printing Defects Shoping

|

Enter your email address to subscribe to this blog and receive notifications of new posts by email. |