Corrugation Box Defects

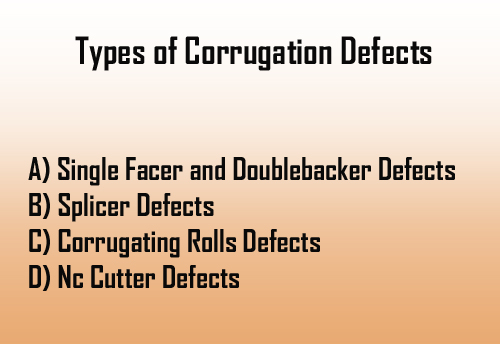

Box defects are problems that can arise during the manufacturing process of corrugated boxes. These issues can stem from a range of factors, including defective machinery, human errors, or low-quality materials. Some of the most common types of box defects include:

1. Crushed corners: This is a defect that occurs when the corners of the box are compressed or damaged due to improper handling or stacking.

2. Delamination: This type of defect results from the separation of the layers of the corrugated material, leading to a weak and unstable box that can easily fall apart.

3. Warp: This is a defect that causes the box to bend or curve due to uneven pressure or improper stacking.

4. Bursting: This type of defect occurs when the box is subjected to excessive weight or pressure, causing it to break open or burst.

5. Poor printing quality: This type of defect results from low-quality printing that can make text illegible or difficult to read.

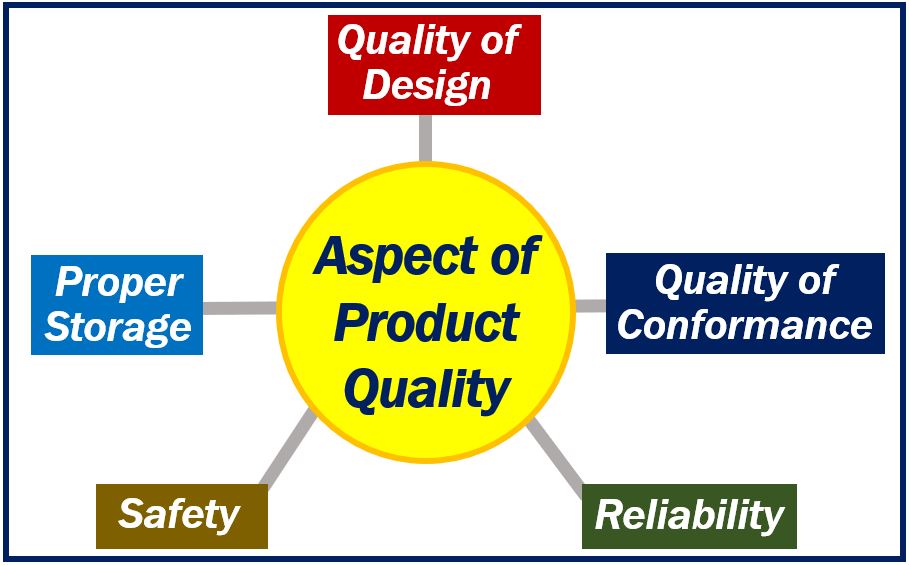

To prevent these defects, manufacturers need to ensure that their equipment is well-maintained and calibrated, and that their employees are trained to handle the materials and products with care. They should also use high-quality materials that are specifically designed to endure the rigors of the production process. By following these steps, manufacturers can reduce the incidence of box defects and enhance the overall quality of their products.

Post By: Ravinder Rana

Popular Posts

Tags

Box Defects Keyline Types of Box Live Class Jobe Corrugation Industrries Defects Formulas Printing Corrugation Defects in box Line defects Printing Defects Shoping

|

Enter your email address to subscribe to this blog and receive notifications of new posts by email. |