Recent updates

Recent updates

Printing New

There are generally four types of printing methods; Screen printing, Offset printing, Digital printing, and Flexo printing. Each of these printing methods has its own unique advantages and disadvantages, and they are used for different applications depending on the type of project, the quantity of prints, and the desired quality of the final product.

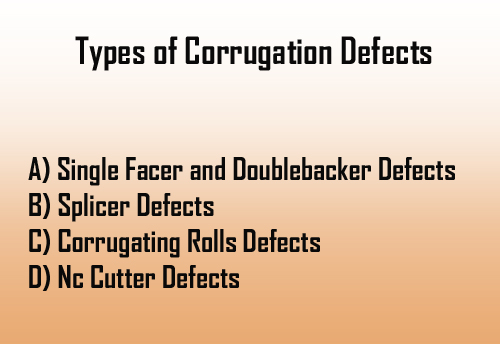

Corrugation New

Corrugation refers to the process of converting paper or cardboard into corrugated board, which is commonly used in the manufacturing of shipping boxes, packaging materials, and other similar products. The corrugation process involves passing the paper or cardboard through a series of machines that create a wavy or ridged pattern in the material, providing it with increased strength and durability. The corrugated board can then be cut and folded into various shapes and sizes according to the customer's needs and the standards requirements such as Board GSM, FCT, B.S, C.S, and Box Weight.Popular Posts

Tags

Home Defects in box Keyline Types of Box Live Class Jobe Corrugation Industrries Defects Formulas Printing CorrugationLine defects Printing Defects Shoping